Did you know that a single speck of dust on a fiber optic connector can cripple your network’s performance? If you’ve ever struggled with slow speeds, mysterious outages, or the headache of mismatched cables, you’re not alone. Choosing the right fiber optic connector isn’t just a technical detail—it’s the backbone of a reliable, high-speed network. In this guide, I’ll walk you through the essentials of picking the perfect connector for your needs, sprinkle in some real-world advice, and help you avoid the pitfalls that trip up even seasoned pros.

Why Fiber Optic Connectors Matter

Let’s face it: not all connectors are created equal. The wrong choice can lead to signal loss, increased maintenance, and costly downtime. Whether you’re upgrading your office network, building out a data center, or future-proofing your infrastructure, understanding connector types and their applications is crucial.

Common Fiber Optic Connector Types (And Where They Shine)

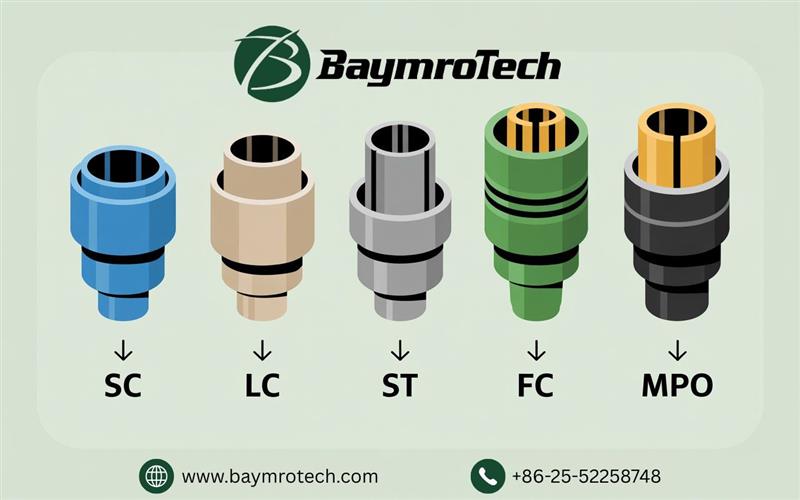

With over a hundred types on the market, it’s easy to get lost in the alphabet soup of SC, LC, ST, FC, and MPO connectors. But don’t worry—I’ll break down the five most common types you’re likely to encounter:

SC (Subscriber Connector)

Shape: Square, 2.5 mm ferrule

Best for: Data centers, telecom, and PON (Passive Optical Network) applications

Pros: Durable, easy push-pull latching, affordable

Cons: Bulky—takes up more panel space

LC (Lucent Connector)

Shape: Compact, 1.25 mm ferrule

Best for: High-density installations (think crowded server racks)

Pros: Tiny footprint, simple latch, great for future-proofing

Cons: Slightly higher upfront cost, but pays off in scalability

ST (Straight Tip)

Shape: Round, bayonet mount

Best for: Legacy multi-mode networks (campuses, offices)

Pros: Quick “twist and lock” connection

Cons: Less common in new installs, can be knocked loose

FC (Ferrule Connector)

Shape: Threaded, robust alignment

Best for: Specialized or legacy applications

Pros: Excellent for precision alignment

Cons: Largely replaced by SC and LC in modern networks

MPO/MTP (Multi-fiber Push On)

Shape: Rectangular, holds 12–24 fibers

Best for: High-bandwidth, parallel connections in data centers

Pros: Supports massive data throughput, saves space

Cons: More complex to manage, requires careful polarity and gender matching

Key Factors When Choosing Your Connector

Let’s cut through the jargon. Here’s what you need to consider before making your pick:

Size & Compatibility: Will it fit your patch panels or keystone jack modules? LC is ideal for tight spaces, while SC offers more robustness.

Performance Needs: High-speed backbone? Go with LC or MPO. Simpler setups? SC or ST might suffice.

Ease of Installation: If you hate fiddly parts, SC’s push-pull or ST’s twist-lock are user-friendly. LC is easy but tiny—watch those fingers!

Future-Proofing: Planning for growth? LC and MPO connectors support higher data rates and denser installations.

Cost: Don’t just look at sticker price. Consider long-term savings from easier maintenance and scalability.

Environment: Harsh conditions? Look for ruggedized or hardened connectors, especially for outdoor or industrial use.

Maintenance: Regular cleaning is a must—dirty connectors are the #1 cause of signal loss. Schedule routine inspections to keep your network humming.

Real-World Example: The Data Center Dilemma

A client of ours was expanding their data center and needed to maximize rack space. They initially used SC connectors but quickly ran out of panel real estate. By switching to LC connectors, they doubled their port density and improved cable management—no more spaghetti mess behind the racks! This simple change saved them both time and money during future upgrades.

How to Avoid Common Mistakes

Don’t mix and match: LC won’t fit an SC port, and vice versa. Double-check compatibility with your keystone jack manufacturer.

Watch for polarity: Especially with MPO/MTP connectors—getting this wrong can mean hours of troubleshooting.

Clean, clean, clean: A dirty connector is a slow connector. Invest in proper cleaning tools and make it part of your routine.

Optimize Your Network with the Right Partner

If you’re sourcing connectors or keystone jack modules, choosing a reputable keystone jack manufacturer is just as important as picking the right connector. Manufacturers based in Shenzhen, China, for example, are known for their advanced production capabilities and cost-effective solutions. For more on finding reliable partners, check out our guide on how to select a keystone jack manufacturer.

Best Practices for Fiber Connector Performance

Preparation: Always clean connector and cable ends before installation.

Handling: Avoid excessive bending or twisting—fiber is tough, but not invincible.

Regular Maintenance: Schedule inspections to catch issues early and prevent downtime.

For a deeper dive into fiber connector maintenance, see our post on fiber optic network care tips.

Expert Opinions & Industry Insights

According to a recent Airtel guide, LC and SC connectors are the gold standard for high-speed, reliable networks. Industry leaders like VCELINK also highlight the importance of matching connector type to your specific application—there’s no one-size-fits-all solution.

Conclusion: Make Your Network Future-Ready

Choosing the right fiber optic connector is about more than just matching shapes—it’s about ensuring performance, reliability, and room to grow. Remember to consider your network’s current needs and future ambitions, and don’t skimp on quality or maintenance.

Ready to take your network to the next level? Explore our fiber optic solutions or get in touch for a personalized consultation. Have a connector horror story or a tip to share? Drop your thoughts in the comments—we’d love to hear from you!